The store will not work correctly when cookies are disabled.

JavaScript seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Javascript in your browser.

Home

American Legend Wheels - Wheel Fitment Guide

American Legend Wheels - Wheel Fitment Guide

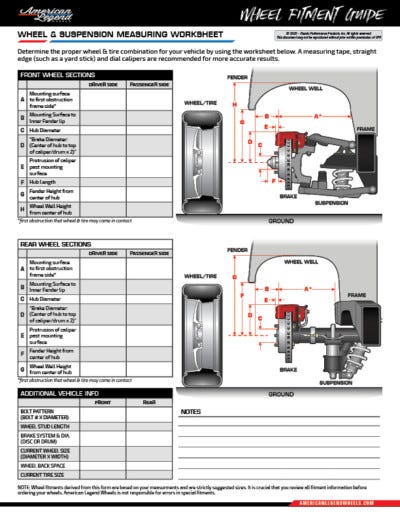

Wheel & Suspension Measuring Worksheet

Determine the proper wheel & tire combination for your vehicle by using the worksheet below. A measuring tape, straight edge (such as a yard stick) and dial calipers are recommended for more accurate results.

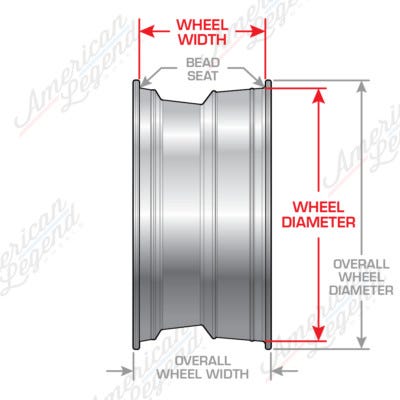

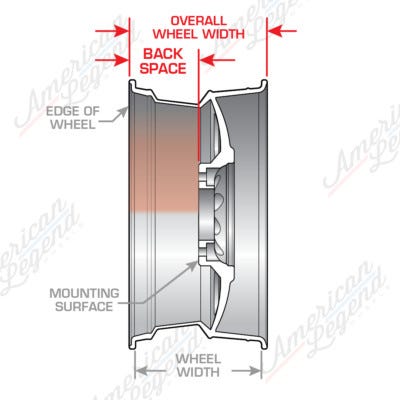

Wheel Width, Diameter, & Backspace

Wheel width is the distance, in inches, measured from bead seat to bead seat across the barrel of the wheel. Wheel width is used to determine compatible tire sizes and directly affects a tire’s contact patch with the ground. Depending on the width of the wheel, it will either enlarge or shrink your tire’s contact patch, leading to changes in your vehicle’s handling characteristics. The “overall wheel width” is used to determine the wheel backspace and front space measurements.

Wheel diameter is the distance, measured in inches, across the face of the wheel, from bead seat to bead seat and is used to determine compatible tire sizes. Only wheels and tires of the same diameter can be safely mounted and paired together along the same axle. As little as a half-inch difference in diameter can lead to unsafe and undesired results. The overall wheel diameter can vary depending on the wheel design and affect clearance.

Backspace is the measured distance from the wheel’s mounting surface to the very back edge of the overall wheel width (not the inner bead face) and is often incorrectly referred to as offset (see Wheel Offsets). This measurement is important when identifying inner wheel clearance closest to the vehicle’s frame and suspension components. Although related, backspace should not be confused with offset.

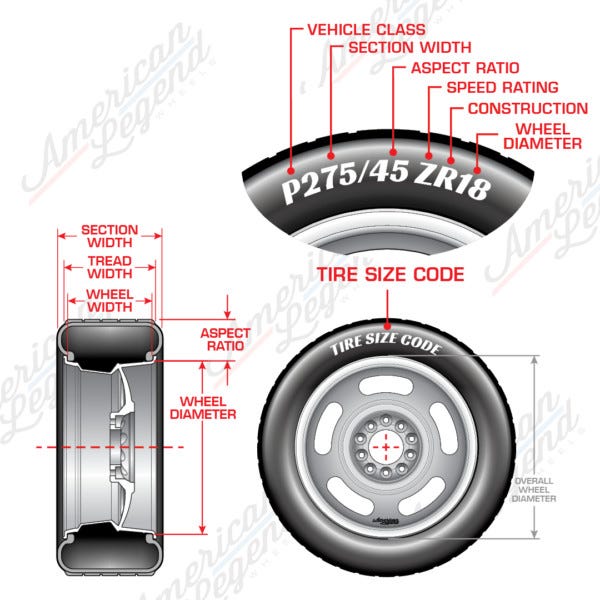

Tire Sizes

TIRE SIZE CODE

SECTION WIDTH

TREAD WIDTH

ASPECT RATIO

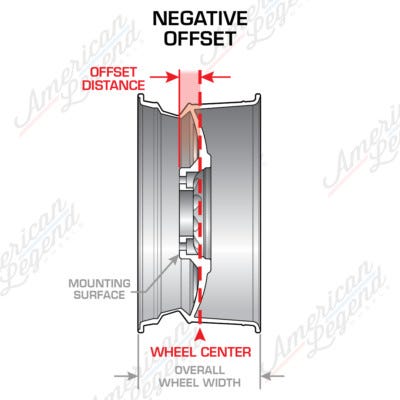

Wheel Offsets

NEGATIVE OFFSET

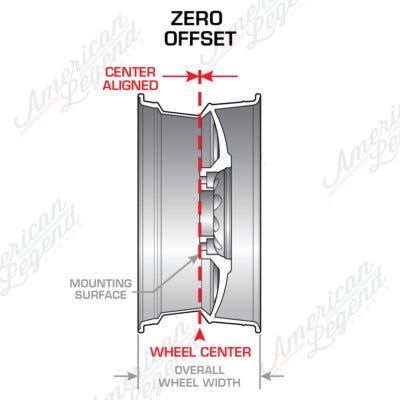

ZERO OFFSET

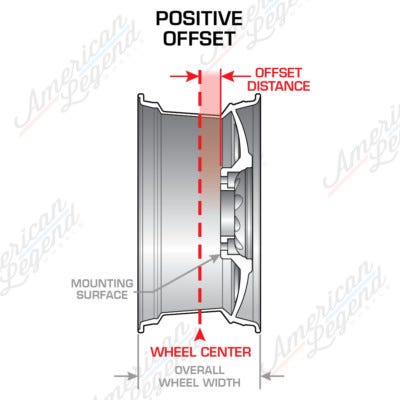

POSITIVE OFFSET

Offset / Backspace Conversion Chart

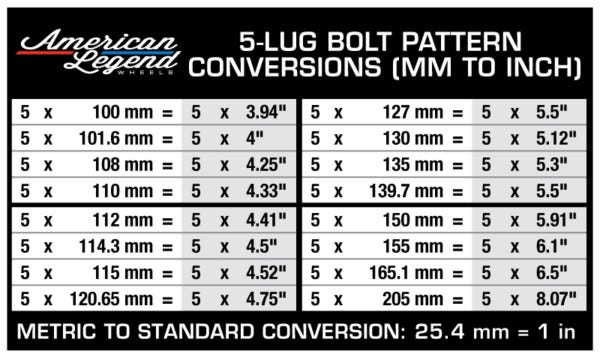

Wheel Bolt Patterns

Bolt patterns are also referred to as stud pattern, bolt circle,

or PCD(Pitch Circle Diameter). The first number refers to the number of

studs/bolt holes, while the second number is the diameter of the imaginary

circle that passes through the center of each stud(or bolt hole). Generally

stated as 5 on 4 ½, or 5×4 ¾ – metric equivalents

include 5×114.3 and 5×120.65. Some wheels have more than one

set of bolt holes such as dual pattern wheels(total of 10 holes), which

allows the same wheel to be fitted to vehicles with a different bolt pattern

or PCD.

5-lug bolt patterns can be difficult to measure since the

bolt holes are not positioned directly across from each other. You can estimate

the measurement by using a straight line from the backside of one hole to

the center of the third bolt hole. To accurately measure and identify your

bolt pattern, use the American Legend Wheels Bolt Pattern Template.

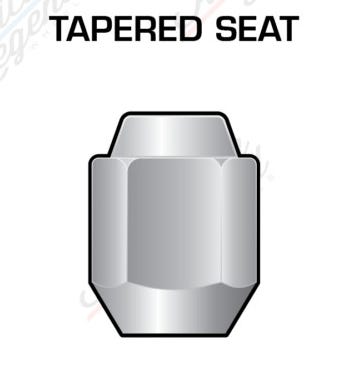

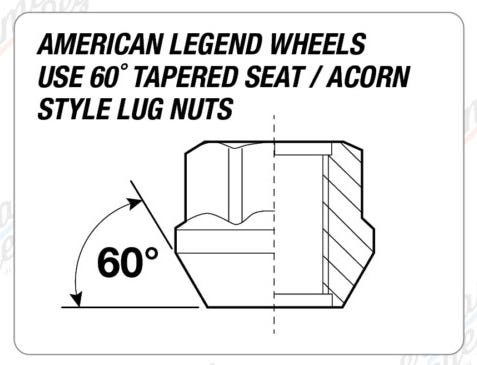

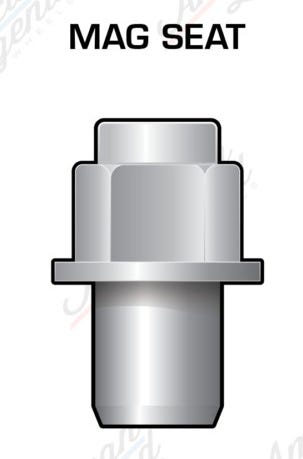

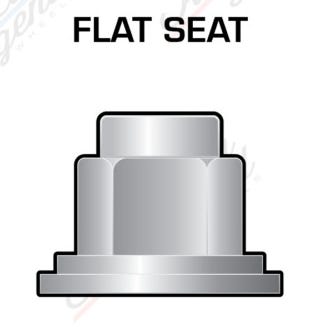

Common Lug Nut Styles

IMPORTANT: It is crucial that the lug nut seat and the

wheel lug seat match. If the lug nut seat type does not match the wheel

seat type, it is possible that the lug nut could damage the wheel, or possibly

cause the lug nut to loosen and the wheel to become unsecured.

Tapered Seat

Mag Seat

Flat Seat

Safety Seat

Before you install your wheels, It is very important to

check your vehicle’s recommended torque specifications and make sure

the lug nut is torqued correctly. If over-tightened, both the lug nut and

the stud can be fatigued, possibly leading to failure.

Bolt Pattern Template

Measuring Bolt Pattern Template

To measure 4, 6 and 8-lug bolt patterns, take your measurement from the middle of two wheel bolts directly across from one another. To measure 5-Lug patterns, take your measurement from the BACK of a wheel bolt to the CENTER of the SECOND wheel bolt. To accurately identify a 5-lug pattern, use the Bolt Pattern Template.

IMPORTANT:

To print to the Bolt Pattern Template the correct dimensions, you must ensure that the “Page Scaling” option in the print settings dialog box is set to “None” or 100%.

How Do I Use The American Legend Wheels Visualizer?

Select YEAR, MAKE, MODEL ETC of your vehicle

Use archive image (if shown) OR click on UPLOAD YOUR OWN

View vehicle photo tutorial video

Take photo then transfer from phone or camera to your computer

Drop the photo image into the box and upload

Click to return to the VISUALIZER

Wheel & Tire – Glossary of Terms

Acorn Wheel Nut

Adapter

Aerospace 6061-T6

Air Pressure

Alignment

Aspect Ratio

Assembly Bolts

Asymmetric

Backspace

Balancing

Barrel

Bead (Tire)

Bead Face

Bead Seat

Bias Ply Tire

Billet

Bolt Pattern

Breaking the Bead

Caliper Clearance/Poke-Out/Stick-Out/X-Factor/Caliper

Height

Camber

Car Configurator

Cast Wheels

Caster

Center Cap

Center Hub

Centering Rings

Center Piece

Centerbore

CNC/CNC Machined

Conical Nut

Contact Patch

Cross Ply

Curb Rash

Deep Dish

Design Rim Width

Diameter (Rim/Wheel)

Directional

DOT/D.O.T.

Dual Pattern

Dynamic Balance

ET

Fitment

Forged

Front Wheel Drive Offset

Gutter Rash

Hoop

Hub/Hub Mounting Face

Hub-Centric

Hub Centric Rings (Hub Rings/Centering Rings)

Inside Barrel

JWL

kPa

Load Rating/Load Index – Tires

Load Rating/Maximum Load – Wheels

Lug Nut (Lugs)

Measured Width

Mirror Polish

Mono-Block

Mounting

Multi-Piece Wheel

Negative Offset

Offset (Positive & Negative)

One-Piece Wheel

Outer Lip

Overall Diameter (Tire)

Overall Diameter (Rim/Wheel)

PCD

Perimeter Bolts

Plus Sizing

Pneumatic Tire

Positive Offset

Pressure Cast

Profile

Pro Street

Pro Touring

PSI

Radial Tire

Rearspace

Reverse Lip

Rim Drop

Rim Lip

Rim Width

Run Flat Tires (RFT)

SAE Standard

Seating/Breaking the Bead

Section Width

Series (Tire)

Shoulder

Sidewall

Sipes

Soft/Smooth Lip

Spacer

Speed Rating

Spoke Insert

Spoke Face

Staggered Fitment/Staggered Width

Step Lip/Stepped Lip

Stud Pattern

Tapered Seat Wheel Nut

Three-Piece Wheel

Tire Diameter

Tire Placard

Toe

Torque Sequence

Track Width/Vehicle Track Width

Tread

Tread Depth

Tread Depth Indicators

Tread Pattern

Tread Width

T.U.V

Two-Piece Wheel

Visualizer

Wear Indicators

Wheel Adaptor

Wheelbase

Wheel Builder/Customizer

Wheel Diameter

Wheel Offset

Wheel Spacer

Wheel Visualizer

Wheel Weights

Wheel Width

Window

Window Accent

Zero Offset

Now that you’re wheel and tire guru, take the time

to browse American Legend’s range of one-piece pressure cast wheels.

Wheel Care – Satin Suede

Satin suede is a sand blasted finish best cleaned with a quality glass cleaner and a clean microfiber cloth. Keep wheels clean avoiding damage to the wheels finish. Do not use harsh cleaning chemicals. Do not use pressure or steam cleaners.

Wheel Care – Chrome

Clean when cool with mild soap, water and non-abrasive cloth. Once cleaned, dry with a clean and non-abrasive towel. Keep wheels clean avoiding damage to the wheels finish. Do not use harsh cleaning chemicals. Do not use pressure or steam cleaners.

Wheel Care – Clear Coat

Clean when cool with mild soap, water and non-abrasive cloth. Once cleaned, dry with a clean and non-abrasive towel. Keep wheels clean avoiding damage to the wheels finish. Do not use harsh cleaning chemicals. Do not use pressure or steam cleaners.

Wheel Care – Powder Coat

Clean when cool with mild soap, water and non-abrasive cloth. Once cleaned, dry with a clean and non-abrasive towel. Keep wheels clean avoiding damage to the wheels finish. Do not use harsh cleaning chemicals. Do not use pressure or steam cleaners.

Wheel Care – Polished

Clean when cool with mild soap, water and non-abrasive cloth. Once cleaned, dry with a clean and non-abrasive towel. Repolish after cleaning with a quality aluminum wheel polish. Keep wheels clean avoiding damage to the wheels finish. Do not use harsh cleaning chemicals. Do not use pressure or steam cleaners.

What is Step Lip?

Step lip rims have one or two steps in the outer lip. The valve hole is located in the lip.

What is Reverse Lip?

Clean when cool with mild soap, water and non-abrasive cloth. Once cleaned, dry with a clean and non-abrasive towel. Repolish after cleaning with a quality aluminum wheel polish. Keep wheels clean avoiding damage to the wheels finish. Do not use harsh cleaning chemicals. Do not use pressure or steam cleaners.